Driving energy efficiency to tackle climate change

Sep 12, 2022 - Reading time 5-7 minutes

“Houston, we have a problem.” These famous words, spoken by Jim Lovell, commander of NASA’s Apollo 13 mission to the moon, must go down as one of the greatest understatements in history. They also stand as an example of humankind’s ability to keep a cool head in the face of adversity – to keep thinking and solve the problem. Qualities we will need as we seek to innovate our way out of the global challenges facing us today.

Apollo 13 was launched from Kennedy Space Center on April 11, 1970. However, the lunar landing was aborted two days into the mission, after an explosion on board vented the oxygen tanks into space. Back on Earth, mission controllers burst into action, improvising new procedures to bring the crew home alive. This included on-the-spot innovation for the energy supply needed to power up the ‘lifeboat’ module for the journey home.

Fast forward 50-plus years – from planetary travelers in urgent need of life-saving solutions to a planet in urgent need of life-saving solutions. Today, climate change is threatening the lives and livelihoods of hundreds of millions of people around the world. And we need to take action fast.

Innovating life-saving solutions

Human health and environmental health cannot be viewed separately [1]. To lead healthy lives, people need a healthy planet. As a health technology company conscious of our responsibility towards society, we are teaming up with our customers and suppliers to innovate solutions that improve people’s health and well-being, while at the same time minimizing environmental impact. That means stepping up our action to mitigate climate change.

As with Apollo 13, we see the sustainable use of energy – along with sustainable use of materials – as a vital part of the solution. On a global level, there is substantial potential for decarbonization in the transition to renewable energy, as well as in improving the lifetime energy efficiency of the devices and systems we use – in our case, those deployed in healthcare [2].

Renewable energy

For large-scale, energy-intensive facilities such as hospitals, switching to renewable energy can make a major impact. Partnering with peers can help achieve the necessary scale. Philips, for example, has secured its renewable electricity supply in Europe through consortium-led power purchase agreements. This has been a key factor in Philips being carbon-neutral in its operations since the end of 2020.

Energy efficiency of devices and systems

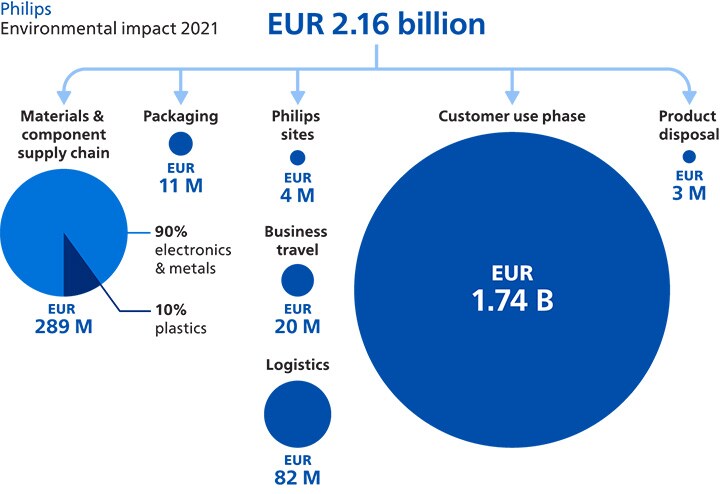

Each year at Philips, we publish an Environmental Profit & Loss account (EP&L), which expresses the total environmental impact of our activities and products – from product design to final disposal by the user – in terms of monetary cost. This provides valuable insight into the main areas where we need to innovate in order to lower our environmental impact.

If we look at our 2021 EP&L above, we see that energy consumption during the customer use phase of our products accounts for around 80% of our total environmental impact. That’s why we are continuously working – through our EcoDesign program – to reduce the energy consumption of all our products.

Introduced at Philips as far back as 1994, EcoDesign is an approach that holistically considers all aspects of product development and design. By applying Life Cycle Analysis as the backbone of our EcoDesign process, we are able to identify and realize significant improvements in four ‘Green Focal Areas’ – energy, substances, packaging, and circularity.

By improving the energy efficiency of a product, we can reduce its energy consumption and carbon footprint. Our Azurion image-guided therapy platform, for example, lowers energy consumption by more than 10% over the system’s total life usage compared to its predecessor [3].

And in the area of diagnostic imaging, our Ingenia 3T MR scanner incorporates PowerSave technology, which adapts gradient energy consumption to the system status to reduce power consumption – switching to lower power modes when the system is not being used for scanning.

Similarly, innovations like our Compressed Sense MR acceleration engine and SmartSpeed AI-based reconstruction software result in shorter scanning times with a limited impact on energy consumption. This means that, for approximately the same amount of energy, the hospital can serve more patients, thereby increasing productivity.

Cross-industry partnering

Philips actively supports a voluntary industry initiative with European trade association COCIR to improve the energy efficiency and material efficiency of medical imaging equipment [4]. COCIR has developed methodologies for measuring the energy consumption of medical devices. As part of the EU Green Public Criteria for medical devices, these methodologies are designed to provide purchasers with all the information they need to calculate running costs and to choose the best equipment for their needs.

Cloud and software as drivers of energy efficiency

The trend towards digitalization can also help improve energy efficiency. For instance, studies have shown that 84% less power is consumed when customers use large, centralized cloud-based data centers instead of on-premises infrastructure [5]. More intelligent and efficient usage of software can lead to potential energy savings of between 30% and 90% [6]. And companies can reduce application energy consumption by up to 50 times simply by selecting the appropriate programming language for the task.

Helping our supply chain to improve energy efficiency

As well as maintaining carbon neutrality in our own operations and driving product and business model innovation, reducing the carbon footprint of our supply chain is key for Philips, as we strive to reduce emissions across our value chain in line with a 1.5 °C global warming scenario.

As part of our Green Supply Chain program, we carry out on-site assessments – e.g. in China – where we identify energy efficiency opportunities that enable our suppliers to make cost-effective carbon reductions. For example, their facilities may have outdated lighting systems, or insulation may be inadequate. Our team calculates for the supplier what the cost impact would be, and also the return. Suppliers have responded positively to these reviews, frequently implementing assessment recommendations.

Failure is not an option

The Apollo 13 mission had a positive ending. Demonstrating technical expertise, resourcefulness and perseverance, the crew and mission controllers succeeded in improvising solutions to the power supply and other critical problems. After almost 6 days in space, the spacecraft splashed down safely in the South Pacific Ocean.

If humankind displays the same unity of purpose, creativity and determination in tackling the problems our planet faces today, we too can overcome adversity. Companies like Philips, with the innovation power and ability to scale solutions, have a vital role to play in this endeavor. But no single party can turn the tide. It takes all of us, working together.

There is a lot that we – private companies, governments, public organizations, but also citizens – can do to drive the transition to a low-carbon economy. Operating carbon-neutral, switching to ‘as a service’ business models, and adopting circular practices, to name just a few. But like the crew of Apollo 13, we have no time to lose.

References

[1] The Lancet, October 2017, https://gahp.net/the-lancet-report-2/

[2] https://www.irena.org/publications/2017/Aug/Synergies-between-renewable-energy-and-energy-efficiency

[3] Determined via the COCIR SRI method. Compared to predecessor Allura Xper platform; Exact energy reduction depends on configuration

[4] https://www.cocir.org/initiatives/ecodesign-initiative/saving-energy.html

[5] https://aws.amazon.com/about-aws/sustainability/

[6] https://www.networkworld.com/article/2861005/energy-aware-software-design-can-reduce-energy-consumption-by-30-to-90.html

[7] Cloud Computing Sustainability & The Green Cloud | Accenture

Stay up to date and subscribe

Sign up to stay informed and receive information on healthcare innovation, straight to your inbox